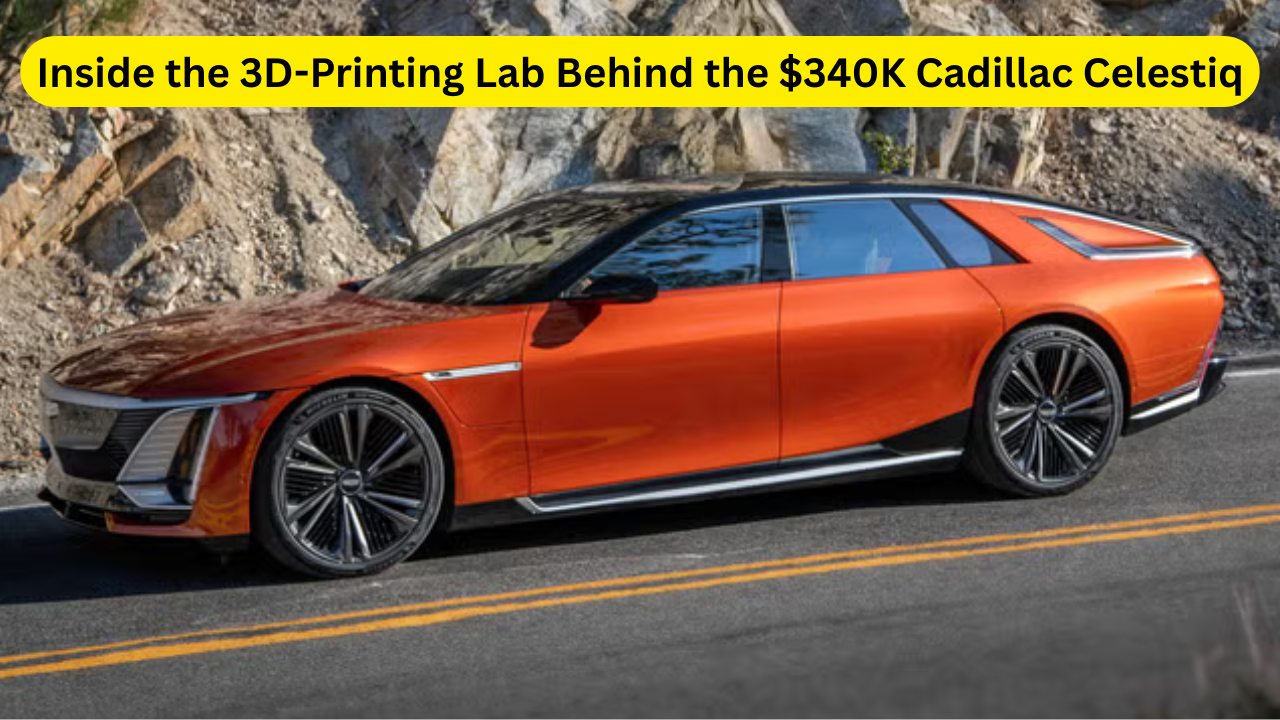

Inside the 3D-Printing Lab Behind the $340K Cadillac Celestiq: In the world of luxury vehicles, innovation is not just about speed or style—it’s about redefining what’s possible. General Motors (GM) has taken a bold leap forward with the Cadillac Celestiq, a $340,000 ultra-luxury electric vehicle that represents the pinnacle of technology and craftsmanship. One of the most groundbreaking aspects of this vehicle isn’t under the hood or inside the cabin but deep within the 3D-Printing Lab at GM’s Additive Industrialization Center (AIC) in Warren, Michigan. This 16,000-square-foot facility is where cutting-edge additive manufacturing techniques are shaping the future of automotive production.

While additive manufacturing—more commonly known as 3D printing—has traditionally been seen as too slow or expensive for mainstream car production, it’s perfectly suited for ultra-low-volume vehicles like the Celestiq. With only 25 hand-built units expected in the first year, GM has embraced 3D printing to produce more than 130 parts using materials such as aluminum, stainless steel, polyamide 11 and 12 (nylon), thermoplastic polyurethane, and polypropylene. These materials are transformed from powdered metals and polymers into precision-crafted parts, not just to save cost but to offer design flexibility and reduce lead times.

The process doesn’t end with simply printing the parts. Each component must pass a rigorous validation process inside the Additive Industrialization Center before it is approved for use. The AIC is not a manufacturing plant; it’s a technology incubator. Engineers test the viability, durability, and feasibility of each component, ensuring that 3D printing meets GM’s high standards for quality and performance. “Our job is to bring in the technology, industrialize it, and move it to the point of manufacturing,” said Brennon White, a GM technical specialist. Once validated, these parts are then manufactured at scale by third-party suppliers. This hybrid model combines innovation with scalability, offering a glimpse into the future of car manufacturing.

Specifications of the Cadillac Celestiq

| Specification | Details |

|---|---|

| Powertrain | Dual-motor AWD electric setup |

| Battery Capacity | 111 kWh Ultium battery pack |

| Range | Estimated 300+ miles (EPA) |

| Horsepower | Approx. 600 hp |

| Torque | 640 lb-ft |

| 0–60 mph Acceleration | Under 4 seconds |

| Charging | 200 kW DC fast charging |

| Chassis | Custom aluminum platform |

| Drivetrain | All-Wheel Drive (AWD) |

| Price | Starting at $340,000 |

Features of the 2025 Cadillac Celestiq

1. Extensive Use of 3D-Printed Parts

Over 130 components of the Celestiq are 3D printed. These include structural parts, interior trims, and even HVAC components. This allows for unmatched customization, lightweighting, and rapid prototyping.

2. Advanced Infotainment System

The Celestiq features a 55-inch pillar-to-pillar LED display, a dual-screen rear entertainment system, and augmented reality navigation, setting a new benchmark in luxury EV infotainment.

3. Smart Glass Roof

Equipped with a four-zone smart glass roof, each passenger can independently adjust the transparency level above their seat—an industry first.

4. Custom Interiors

Each Celestiq is bespoke, offering hand-stitched leather, real metal, and wood trim, curated to the buyer’s preferences. This truly makes every unit one of a kind.

5. Ultra Cruise

GM’s Ultra Cruise driver assistance system builds on Super Cruise and enables hands-free driving on over 95% of U.S. roads.

Also read: Mercedes-Benz SLS AMG ‘FAB Design Gullstream: A Rare Masterpiece of Power and Design

Performance: Power Meets Precision

The Celestiq isn’t just a luxury showpiece—it’s a high-performance electric sedan. It’s powered by GM’s Ultium platform, utilizing dual motors that produce around 600 horsepower and 640 lb-ft of torque. This all-electric powerhouse accelerates from 0 to 60 mph in under 4 seconds, rivaling sports sedans while offering the silent elegance of an EV. The 111 kWh battery pack supports over 300 miles of range and is compatible with 200 kW DC fast chargers, giving drivers both performance and practicality.

Suspension duties are handled by a multilink adaptive air suspension system, ensuring a smooth, responsive, and customizable ride. Coupled with rear-wheel steering, the Celestiq delivers superb handling dynamics despite its large footprint.

Design: Bespoke Elegance

Exterior Design

The Celestiq blends futuristic design with Cadillac’s traditional elegance. Its long, low-slung silhouette, sweeping fastback roofline, and expansive grille exude confidence. With aerodynamic styling and striking LED lighting, the Celestiq is unmistakably modern while staying true to Cadillac’s Art & Science design language.

Interior Design

The cabin is a masterpiece of modern luxury. With handcrafted materials, customizable trim, and 3D-printed accents, every interior tells a unique story. The pillared digital dashboard, ambient lighting, and multi-zone climate control enhance the immersive experience. Cadillac also uses 3D-printed trim pieces, seamlessly integrated into the overall aesthetic.

Additive Manufacturing: The Future of Customization

GM’s use of additive manufacturing has allowed designers to explore intricate geometries and lightweight components that traditional manufacturing cannot easily replicate. From plastic HVAC ducts to metal structural supports, 3D printing offers a level of precision and flexibility previously unimaginable.

Why 3D Printing Makes Sense for the Celestiq

- Low Production Volume: Only 25 units in the first year, increasing in later cycles.

- Customization Demand: Each car is tailor-made, requiring unique parts.

- Cost-Effective Prototyping: 3D printing reduces development time.

- Supply Chain Flexibility: On-demand printing lowers inventory overhead.

Launch Date and Availability

The Cadillac Celestiq officially launched in 2023, with the first customer deliveries scheduled throughout 2024 and into early 2025. The vehicle is built at GM’s Global Technical Center in Warren, Michigan—specifically within a dedicated Artisan Center where each vehicle is hand-assembled.

Cadillac plans to continue producing Celestiq in extremely limited numbers, focusing on bespoke orders and ultra-premium clientele. Orders can be placed via select Cadillac dealers or directly through the brand’s concierge service.

Cadillac Celestiq: Pricing and Customization

| Trim | Starting Price | Customization |

|---|---|---|

| Single Trim Model | $340,000+ | Fully Bespoke, Custom Interior/Exterior |

Due to its hand-built nature and custom options, the Celestiq’s price can easily exceed $400,000, depending on the complexity and choice of materials, paints, and technology integrations.

Cadillac Celestiq Conclusion

The Cadillac Celestiq stands as a symbol of American luxury, innovation, and craftsmanship. With its extensive use of 3D printing and additive manufacturing, GM has not only pushed the boundaries of what’s possible in automotive engineering but has also reimagined the role of customization in luxury vehicles. Each part printed, each interior tailored, and each detail hand-assembled speaks to a new era of elite automotive personalization.

In embracing technologies that were once deemed impractical for large-scale automotive use, Cadillac has shown that limited production can be a fertile ground for technological evolution. The Celestiq isn’t just a car; it’s a statement—one that places GM and Cadillac squarely at the forefront of the future of luxury electric vehicles.

Cadillac Celestiq FAQs

1. Why is GM using 3D printing for the Cadillac Celestiq?

GM is using 3D printing for the Celestiq because it allows for highly customizable, low-volume production. Additive manufacturing is ideal for producing intricate parts without the high upfront costs of traditional tooling, making it perfect for a car like the Celestiq that will be produced in very limited numbers.

2. How many parts of the Celestiq are 3D printed?

More than 130 parts of the Celestiq are produced using additive manufacturing. These parts include structural components, trim pieces, HVAC parts, and brackets made from aluminum, stainless steel, and high-performance plastics.

3. Can I customize every part of my Cadillac Celestiq?

Yes, the Celestiq is fully bespoke. From interior trims to exterior finishes and even certain structural elements, each customer works with Cadillac to personalize every detail of their vehicle, making each unit unique.

4. Where is the Cadillac Celestiq built?

The Celestiq is hand-built at GM’s Artisan Center inside its Global Technical Center in Warren, Michigan. Each vehicle is assembled by master craftspeople, blending traditional skills with cutting-edge additive technologies.